We provide the best possible and most comprehensive stainless steel production solutions for the bioprocessing and production projects at customers' businesses. Whether you are a company under pharmaceutical and food processing category looking for sanitary stainless steel vessels, reaction and fermentation tanks for large-scale production, or a R&D laboratory hoping to work with stainless steel laboratory equipment, pilot scale bioreactors and fermenters, RITAI is a reliable source for your cell culture optimization, fermentation and batch production needs.

Shanghai Ritai Medicine Equipment Project Co., Ltd. (RITAI) has been dedicated to the R&D of sanitary stainless steel pressure vessels, atmospheric vessels, sanitary valves, and sanitary piping systems, which are extensively utilized in the chemical, pharmaceutical, biological, cosmetic, and food industries since its establishment. RITAI is a proud member of the Chinese Pharmaceutical Equipment Industry Association and the Shanghai Special Equipment Management Association. The company's quality management system is rooted in ISO9001 and holds the manufacturing license for Class I and II pressure vessels in the People's Republic of China, as well as the American ASME (U) stamp.The design and manufacture of our products are in compliance with European Pressure Equipment Directive 2014/68/EU (PED).

RITAI animal cell culture R&D center has the capability of cell strain preservation, culture condition screening, high-density culture on microcarriers, fibra disk culture, suspension cell culture and optimization of conditions, as well as bioreactor validation. We can provide customers with services and technical cooperations such as large-scale culture training and guidance, preparation of experimental samples, optimization of tank culture conditions, cultivation scale-up, and rental of experimental equipment, to save costs and time for pharmaceutical development enterprises.

Tell us more about the products and services you're interested in—as well as which industry you call home—on our quick-and-easy "Request for Information" form. Or, give us a call and talk to one of our representatives.

Our stainless steel vessels and processing equipment have gained popularity not only in China but also in export markets such as the Netherlands, Italy, Jordan, Saudi Arabia, Vietnam, India, Indonesia, Mexico, and Russia.

We are committed to delivering high-quality bioreactor solutions for clients in the biopharmaceutical, biotechnology, and bioengineering industries—powered by our expert design team, efficient in-house construction capabilities, strict environmental controls, advanced processing equipment, strong R&D center, and rigorous quality management system.

-

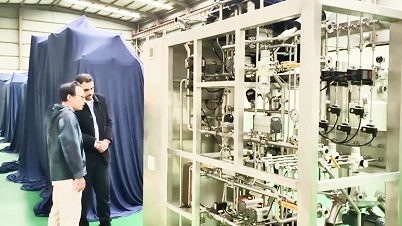

R&D Center

R&D Center

Our facility features a 1,000 m² cleanroom laboratory equipped with a complete set of instruments and specialized equipment covering the entire biopharmaceutical upstream and downstream processes.

-

Quality Management

Quality Management

We implement comprehensive Factory Acceptance Testing (FAT) protocols covering critical elements such as pure steam, deionized water, clean air, and power supply.

-

Construction Team

Construction Team

With a skilled team of over 170 production and management professionals, we handle every manufacturing step in-house – no subcontracting required.

-

Environmental Control

Environmental Control

All construction takes place within cleanroom environments to tightly control iron ion contamination. Our facility features ventilation systems that maintain a slight positive pressure, effectively keeping out dust.