CIP Cleaning Systems

As a professional company providing stainless steel manufacturing services, RITAI is capable of offering high quality CIP cleaning systems tailored to different industries like pharmaceutical, chemical and food. In addition to stainless steel clean-in-place stations, we also provide modular process system solutions to meet your specific needs.

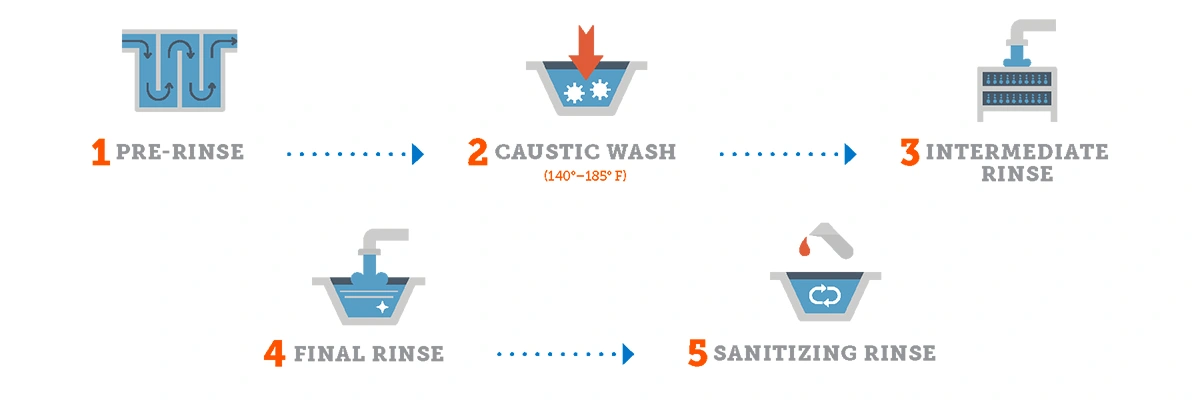

CIP (Cleaning-in-Place) is a method used to clean and sanitize equipment without dismantling it, and it is an independent process module that typically operates in a passive mode. According to your cleaning process, RITAI can provide fixed or mobile single-tank, dual-tank, or multi-tank configurations. The cleaning solution is typically a mixture of water and cleaning agents, including detergents, acids, or alkalis, depending on the type of equipment being cleaned and the type of soil to be removed. These systems can also be equipped with heating functions and more.

At RITAI, our CIP cleaning process is fully automated. Customers can flexibly adjust the formula to meet the requirements of different production processes through a human-machine interface and graphical display. The system can also automatically regulate various process parameters such as cleaning time, pressure, flow rate, and temperature, as well as automatically prepare different detergent concentrations and automatically monitor the effectiveness of CIP cleaning. Furthermore, all operations can be recorded for system certification.

CIP systems are used in industries that require regular and efficient cleaning of process equipment and pipelines without the need for disassembly.

Dedicated Manufacturer of Bioprocess Equipment Shanghai Ritai specializes in high-end Bioreactors, Fermenters, and Modular Process Systems for the global biopharmaceuticals, enzyme production, and bio-agriculture industries. Beyond premium stainless steel fabrication, we deliver turnkey engineering solutions—from conceptual design and ASME-certified manufacturing to installation and GMP-compliant validation. Trusted by clients worldwide, RITAI ensures your critical equipment meets the strictest international standards, including ASME (U) Stamp, EU PED, and FDA regulations.