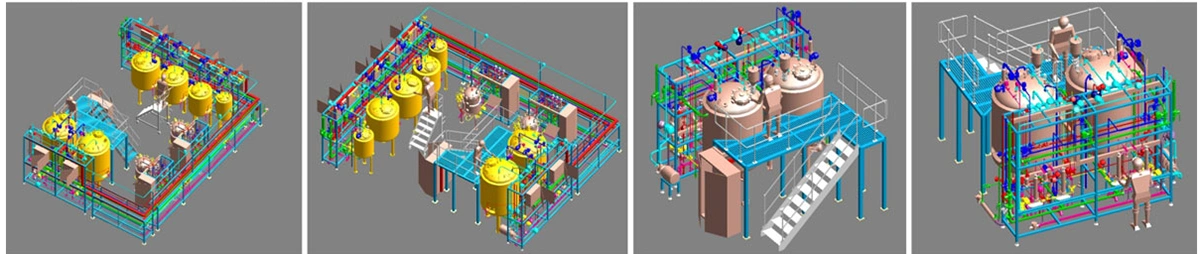

- Cell Culture Systems

- Microbial Fermentation Technology

- Biomass Harvesting Systems

- Biological Filtration Systems

- Bio-Inactivation Systems

- Bio-Waste Inactivation Systems

- Liquid Preparation Modules

- CIP (Clean-in-Place) Systems

- Other customized process modules

In the core production processes of biopharmaceuticals, biotechnology, and bioengineering, modular process system plays a critical role in reducing the risks of cross-contamination and microbial contamination.

At RITAI, we specialize in designing and manufacturing tailor-made sanitary modular process systems that meet the world’s most demanding standards, including SFDA, FDA, WHO, and EU cGMP. Our solutions are built to support cutting-edge applications such as vaccine production, cell and gene therapy, protein engineering, and the development and biologics manufacturing.

From concept to commissioning, our expert team provides full-spectrum design and engineering services, delivering high-performance stainless steel equipment and fully customized skid-mounted systems. With a proven track record in modular system integration, we offer solutions that optimize efficiency, ensure product quality, and accelerate your path to market.

- Design Team

With a team of 62 skilled professionals, our design department brings together deep industry expertise and cutting-edge global standards. Each department is equipped with advanced software and a clearly defined workflow, enabling seamless collaboration across all stages of design. Through close collaboration, we deliver optimized and customized process solutions to meet our clients’ specific needs. - Advanced Manufacturing

All fabrication takes place in high-grade sanitary workshops to eliminate iron ion contamination. Backed by world-class manufacturing equipment, we have achieved over 90% automation in our tank production process, ensuring outstanding quality, consistency, and rapid turnaround times. - R&D Innovation Center

Spanning 1,000 m², our R&D center is equipped with a full suite of upstream and downstream biopharmaceutical instruments, as well as specialized tools for product development and process optimization.

- Rigorous Quality Management

Our comprehensive FAT (Factory Acceptance Test) procedures simulate actual working conditions, including clean steam, deionized water, purified air, and power supply, ensuring every system is fully tested and production-ready before delivery. - In-House Installation and Construction Team

With more than 170 experienced engineers and production staff, we offer full in-house manufacturing – no outsourcing required. This allows us to maintain strict quality control, faster lead times, and seamless project coordination. Our production capacity reaches up to 80 tanks per month, customized to a wide range of sizes and specifications.