For bioprocessing companies, heat exchange treatment is an essential step that can reduce the temperature of bioprocessing equipment and processing liquids. It also enables heat recovery for reuse through thermal cycling. RITAI provides various types of heat exchangers to pharmaceutical companies, chemical manufacturing enterprises, and others, meeting their needs for temperature reduction and heat recovery.

-

- Sanitary Tube-in-Tube Heat Exchanger RITAI sanitary tube-in-tube heat exchanger is specially designed for cooling processes of injection water (WFI) with a flow rate less than 1500 Lph. This heat exchange consists of two tubes, an inner and an outer coiled together, which ensures rapid cooling, minimal maintenance, and no risk of cross-contamination between the product and working fluids. View More

-

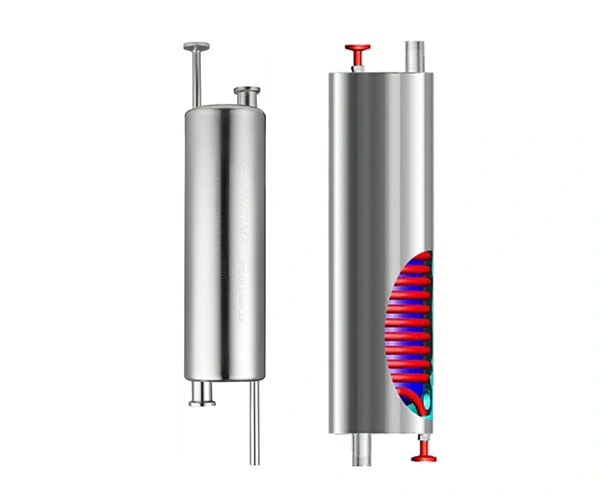

- Sanitary Miniature Shell & Tube Heat Exchanger Shell and tube heat exchangers are designed with double tubesheet to prevent cross contamination, and can be classified as parallel flow heat exchangers and countercurrent flow heat exchangers based on the direction of liquid flow, which depends on the positions of the liquid inlet and outlet. The choice between parallel and countercurrent systems will affect the heat transfer and pressure of the bioprocessing system. The selection should be based on the actual conditions of the bioprocessing system. View More

-

- Sanitary Shell & Tube Heat Exchanger RITAI Sanitary shell & tube heat exchanger is specifically engineered for demanding applications, such as the heating or cooling processes of injection water (WFI), purified water (PW), and pharmaceutical products. This heat exchanger is equipped with a double tubesheet to prevent the mixing of tube-side fluid and shell-side fluid, ensuring sanitary operation, effectively preventing cross-contamination between the product and the service medium responsible for temperature control. View More

-

- Pure Steam Sample Condenser RITAI pure steam sample condenser is a portable unit designed to allow Clean Steam (CS), high-purity steam, and Water For Injection (WFI) samples to be taken quickly and safely at any point within a steam system whilst maintaining a sterile testing environment. The cooling water connections are 3/4″ clamp compatible, which enables the unit to be connected easily to a local water supply. The entire sample condenser is suitable for autoclaving. View More