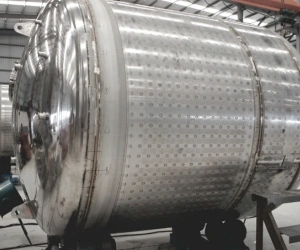

Stainless Steel Sanitary Tanks & Vessels

As a professional company providing stainless steel manufacturing services, RITAI is capable of offering high quality stainless steel sanitary tanks and vessels tailored to different industries like pharmaceutical, chemical and food. In addition to stainless steel sanitary tanks and vessels, we also provide modular process system solutions to meet your specific needs.

RITAI is specialized in the manufacturing of stainless steel tanks and pressure vessels for industries such as pharmaceuticals, beverages, chemicals, etc. With over ten years of experience in the production of stainless steel pressure vessels, we can design and manufacture stainless steel tanks and pressure vessels ranging from 1 L to 50,000 L, following standards and specifications such as GB, ASME, PED, etc.

By utilizing advanced stainless steel sheet processing technology, stainless steel welding technology, electrolytic polishing technology, and mechanical polishing technology, RITAI stainless steel tanks and pressure vessels fully meet the requirements of GMP and FDA regulations. Our sanitary tanks and vessels are widely used in pharmaceutical companies, biopharmaceutical companies, chemical plants, beverage manufacturing companies, and are highly regarded in countries such as the Netherlands, Italy, Jordan, Saudi Arabia, Vietnam, India, Indonesia, Mexico, Russia, etc.

RITAI stainless steel tanks and pressure vessels can be customized according to different industries, including:

Chemical Vessels and Tanks

- Advantages

Used for storing chemicals.

Chemical vessels and tanks are used for chemical processes.

Designed and manufactured according to customer requirements.

Capacity ranges from 1 L to 50,000 L. - Overview

Heat, acid, and steam: Chemical tanks and chemical (pressure) vessels must withstand special stresses. That is why our engineers use high-quality stainless steel grades in the manufacturing process of stainless chemical vessels and tanks. This ensures that the stainless steel vessels and tanks can withstand various chemicals used in processes ranging from water treatment to production of cleaning agents. Our chemical vessels and tanks meet all industry requirements, standards, and process certifications. - Material

For chemical, pharmaceutical and paper industries:

For strong corrosion resistance and resistance to reactive substances, it is generally recommended to use materials such as 304L and AISI 304 for processing stainless steel vessels and tanks.

Used in refining processes:

In refining processes, there are many highly corrosive and harmful substances involved. Therefore, it is generally recommended to use high-alloy austenitic steel, duplex or super duplex steel (1.4462, 1.4460, 1.4501, 1.4507), and super ferritic steel for processing stainless steel vessels and tanks.

Pharmaceutical Tanks

Stainless steel tanks and pressure vessels for validated processes

- Advantages

Used for the manufacturing of pharmaceutical reagents, cultivation of vaccines, and other purposes Pharmaceutical tanks used for formulation processes Designed and manufactured according to customer requirements Capacity ranges from 1 L to 50,000 L - Overview

Pharmaceutical manufacturing must adhere to the highest quality standards, because it revolves around the health of consumers and patients. RITAI is an experienced supplier in the field of pharmaceutical tanks and equipment. Whether you need a medicine mixing tank built according to an existing concept to maintain a validated process or a pharmaceutical storage tank, our engineers will be more than happy to collaborate with you actively.

Beer Tanks

Stainless steel tanks & pressure vessels for breweries

- Advantages

Customize beer tanks for breweries worldwide Fermentation tanks and storage tanks are available in capacities ranging from 1L to 50000L. Heating, cooling, and insulation jacket are optional. Can be processed into various shapes and sizes to suit all applications. - Overview

We manufacture various stainless steel tanks for the beer industry, ranging from small tanks for catering purposes to large fermentation and storage tanks for large breweries. We offer customized services to meet your needs in beer brewing and storage.

Food Tanks & Vessels

Stainless steel tanks and pressure vessels for food process

- Advantages

Designed and manufactured according to customer requirements. Certified food tanks and vessels suitable for various processing methods. - Overview

Are you in search of a sanitary and reliable solution for storing and processing your food and beverages? Look no further than RITAI, and we manufacture and supply stainless-steel tanks and pressure vessels suitable for various applications, including raw milk tanks, cream tanks, fish oil tanks, edible oil tanks, and crystallizers. Our engineers will collaborate with you to develop designs for your aseptic tanks, ensuring a more sanitary and safe storage solution for your products. Please feel free to contact us for more information about our food tank and vessel solutions. - Quality

At RITAI, we are specialized in manufacturing high-quality stainless-steel food tanks for various industries. Our tanks are designed to meet the stringent requirements of the food industry, providing reliable protection for your products and ensuring they are stored according to your needs. The stainless-steel food tanks designed, manufactured, and delivered are the ideal solution for storing and processing food products. These tanks have a highly sanitary structure and can be equipped with efficient mixing systems to ensure product quality, making them an efficient and reliable choice for storing different types of food.

Process Tanks

The right stainless steel tank & pressure vessel for any industry and any process

- Advantages

In industrial production and manufacturing, various types of process tanks are commonly used. Different industries have different processes for handling different products. RITAI has extensive knowledge in the processing of stainless steel tanks and pressure vessels, allowing us to easily integrate with your specific requirements. - Overview

Stainless steel process vessels or reactors are complex storage tanks in which multiple factors come into play. Our engineers will work with you to design stainless steel process tanks and pressure vessels that meet your processing needs, such as mixing, pressure, and heating, and design better connector options for your stainless-steel process tanks. They also understand all typical tank designs and accessories applicable to your industry, whether it's mobile process vessels for the pharmaceutical industry or CCT tanks for the beer industry.

- The material options for sanitary tanks and vessels include 316L, 304, 904L, titanium alloy, super stainless steel, Hastelloy, etc.

- The design and manufacturing comply with ASME, BPE, cGMP and FDA requirements.

- The inner surface is mechanically and electrolytically polished, achieving a surface finish of Ra 0.28-0.4μm.

- Shell dimple, integral, and half-pipe jacket options are available for heating or cooling purposes.

- Chlorine-free insulation materials are used for austenitic stainless steel, and the outer shell is constructed with a welded structure for easy cleaning.

- Accessory options include sight glasses, viewports, handholes (manholes), weighing systems, instrumentation, mechanical and magnetic agitator bridge, etc.

Dedicated Manufacturer of Bioprocess Equipment Shanghai Ritai specializes in high-end Bioreactors, Fermenters, and Modular Process Systems for the global biopharmaceuticals, enzyme production, and bio-agriculture industries. Beyond premium stainless steel fabrication, we deliver turnkey engineering solutions—from conceptual design and ASME-certified manufacturing to installation and GMP-compliant validation. Trusted by clients worldwide, RITAI ensures your critical equipment meets the strictest international standards, including ASME (U) Stamp, EU PED, and FDA regulations.