Sanitary Tube-in-Tube Heat Exchanger

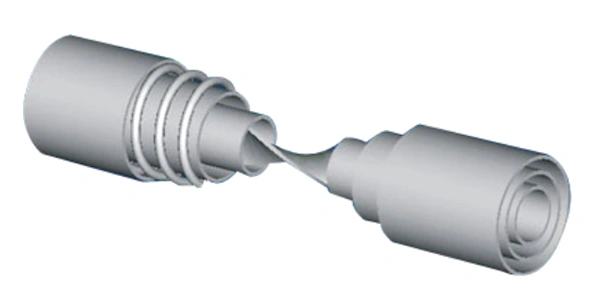

RITAI sanitary tube-in-tube heat exchanger is specially designed for cooling processes of injection water (WFI) with a flow rate less than 1500 Lph. This heat exchange consists of two tubes, an inner and an outer coiled together, which ensures rapid cooling, minimal maintenance, and no risk of cross-contamination between the product and working fluids.

| Model | Flow Rate | Temperature |

| 0-1000lph | Cooled from 85℃ to 40℃ by water entering at 7℃ | |

| 1000-1500lph | Cooled from 85℃ to 40℃ by water entering at 7℃ |

- The entire heat exchanger is made up of three layers of seamless steel tubes, formed in one piece without any risk of leakage (no internal welding). It is manufactured as an integral structure. There is a disturbance device between the two tubes on the cooling medium side to enhance the heat transfer effect. On the product side, there are no cervices or dead corners.

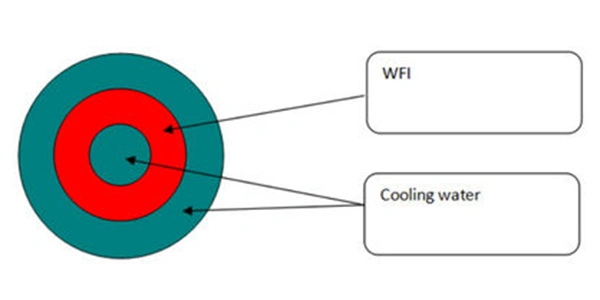

- The product flows through the central channel, while the cooling medium flows through the inner and outer layers of the heat exchanger. The three-layer tubes are bent into a U-shaped design, allowing for the elimination of any thermal expansion generated during heating, cooling, or even steam sterilization with large temperature differentials. The counter-current flow design ensures optimal heat transfer efficiency and a greater cooling range.

- RITAI sanitary tube-in-tube heat exchanger can be sold as a single unit or as a complete modular system, with the modular option being easier to install and use. The module consists of a tube-in-tube heat exchanger, an outer casing, valve assembly, and Pitot tube interface. Our specially customized Pitot tube interface is used for connecting the heat exchanger to the main pipeline system.

- No internal welding to prevent internal leakage Product contact surfaces are electropolished to a surface finish of Ra<0.5mm

- High-efficiency heat conduction ensures rapid heat transfer response (10s)

- Outlet temperature indication ensures the safety of operators

- Compact size, modular design: allows easy installation in the WFI system and saves space

- Special forged interface ensures complete drainage on the product side

- Easy to perform online steam sterilization or hot water sterilization

- Complete documentation system

- The main body of the heat exchanger requires no maintenance

- The U-shaped heat exchanger is resistant to heat-induced deformation

- Heat exchange system in the chemical industry

- Heat exchange system in food manufacturing plants

- Heat exchange system in the gas industry

- Heat exchange system in the metallurgical industry

Dedicated Manufacturer of Bioprocess Equipment Shanghai Ritai specializes in high-end Bioreactors, Fermenters, and Modular Process Systems for the global biopharmaceuticals, enzyme production, and bio-agriculture industries. Beyond premium stainless steel fabrication, we deliver turnkey engineering solutions—from conceptual design and ASME-certified manufacturing to installation and GMP-compliant validation. Trusted by clients worldwide, RITAI ensures your critical equipment meets the strictest international standards, including ASME (U) Stamp, EU PED, and FDA regulations.