As a company specializing in stainless steel tanks & vessels and sanitary-grade process equipment, RITAI is able to provide the most comprehensive stainless steel fabrication solutions for enterprises in the pharmaceutical, biotechnology, chemical, food, and beverage industries.

Design Engineering Our design department expertly integrates GMP requirements for pharmaceutical equipment with our deep industry experience to deliver designs that not only meet functional needs but also optimize manufacturability and process efficiency. Utilizing advanced design software, we provide drawings for client review within the agreed timeframe. Any client feedback or requested revisions are seamlessly incorporated before the design is passed on to our materials, process, inspection, manufacturing, and project control teams, ensuring a smooth, collaborative workflow from concept to completion.

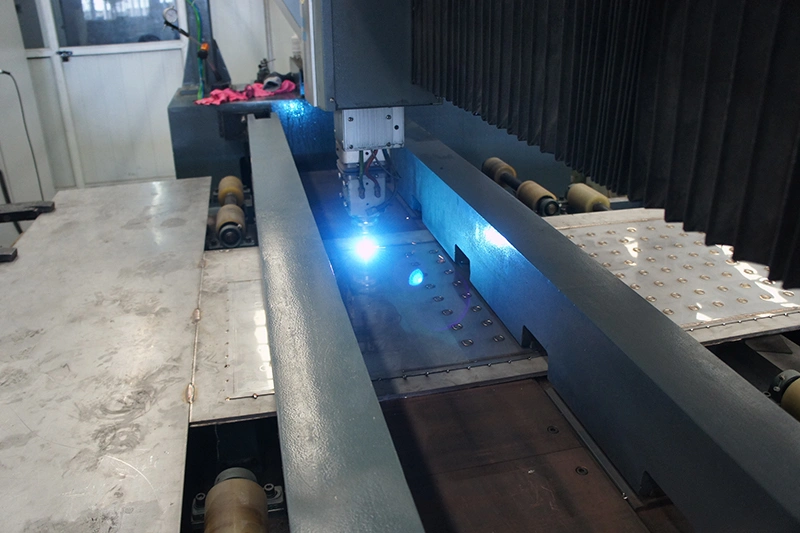

Sanitary Welding We use German EWM welding machines for longitudinal and circumferential seams, and German ROFIN laser welding machines for the jackets. High-purity argon shielding gas all internal welds, significantly reducing defects. Each weld is clearly marked with a unique trace number, welder ID, and weld seam number to ensure full traceability.

Electropolishing & Mechanical Polishing At RITAI, we use advanced automated polishing technology to deliver a consistent finish of 60 to 100 grit in a single pass for both heads and shells. This is followed by precision cloth polishing, achieving a surface roughness of 0.4 to 0.28 μm. For applications that demand the highest level of cleanliness, our cutting-edge electropolishing process ensures an ultra-smooth 0.2 μm finish – fully compliant with ASME and GMP standards. This ensures operational safety, and long-term durability in every vessel we produce.

Field Service We offer on-site support for process equipment across various industries, whether you are a pharmaceutical or food manufacturer in need of stainless steel tanks and vessels, or a laboratory seeking bioreaction and fermentation systems. Our dedicated field service team prioritizes safety and customer satisfaction, delivering on-site installation, commissioning, and maintenance services for your projects. Our services bolster system reliability by addressing issues that may arise during installation and commissioning processes. Our skilled service personnel can assist you in mastering equipment operation and maintenance, ultimately enhancing production efficiency.

Validation Service In addition to delivering top-quality equipment and construction, RITAI also provides validation support to customers. Our validation team comprises engineers from foreign GMP consulting firms, reputable domestic GMP validation testing companies, and professionals with hands-on experience in pharmaceutical facilities. With a profound understanding of the pharmaceutical industry, a background in validation consulting, and extensive practical knowledge of both domestic and international GMP regulations, our team is equipped to deliver validation services that adhere to FDA, EU, TGA, CFDA, and other GMP requirements.

After-Sales Service Our after-sales service includes post-delivery repairs and technical support. Our customer service team responds promptly to your needs and provides assistance and guidance whenever necessary. Additionally, our dedicated engineers inspect your stainless steel tanks and process equipment, offering troubleshooting solutions to ensure smooth operation. If any components show signs of damage, we provide the corresponding spare parts to help minimize downtime and ensure uninterrupted production.