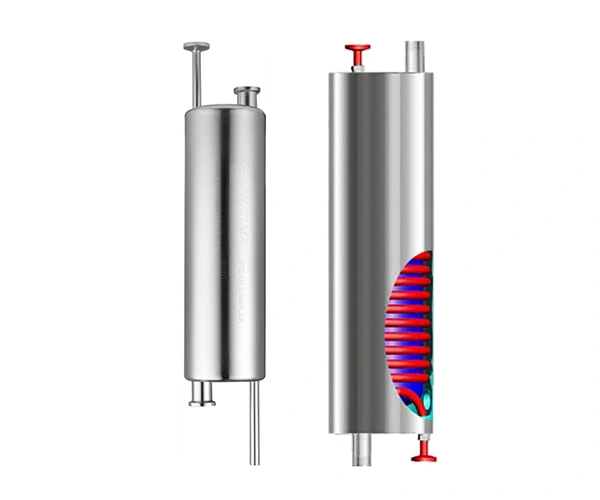

Pure Steam Sample Condenser

RITAI pure steam sample condenser is a portable unit designed to allow Clean Steam (CS), high-purity steam, and Water For Injection (WFI) samples to be taken quickly and safely at any point within a steam system whilst maintaining a sterile testing environment. The cooling water connections are 3/4″ clamp compatible, which enables the unit to be connected easily to a local water supply. The entire sample condenser is suitable for autoclaving.

- Cooling water: 3/4" clamp connections

- Sample medium: 1/2" clamp connections

- Cooling area: Approx. 0.113㎡

- Sample pressure: 15bar

- Sample tube length: 80mm(OD) * 260mm

- Flow condensing samples (steam): 160ml/min

- Cooling water flow (20 ℃): 6L/min

- Heat recovery or cooling systems in food processing systems

- Chemical treatment systems

- Pharmaceutical manufacturing companies

- Waste heat recovery systems

Dedicated Manufacturer of Bioprocess Equipment Shanghai Ritai specializes in high-end Bioreactors, Fermenters, and Modular Process Systems for the global biopharmaceuticals, enzyme production, and bio-agriculture industries. Beyond premium stainless steel fabrication, we deliver turnkey engineering solutions—from conceptual design and ASME-certified manufacturing to installation and GMP-compliant validation. Trusted by clients worldwide, RITAI ensures your critical equipment meets the strictest international standards, including ASME (U) Stamp, EU PED, and FDA regulations.